Misunderstanding Force Sensors

When you hear the term force sensor, force transducer, or load cell, it’s natural to imagine a device that measures force directly. But the reality is that what most call a 'force sensor' doesn't detect force at all. Instead, they measure strain, and convert it into an electrical signal. Once all components are calibrated, this signal can be amplified to display an accurate reading of any unit specified in BS 350:2004 (force, mass, stress, pressure etc.)

In this article, we're going to be looking at the most common methods of measuring strain and how they differ from one another, in both functionality and performance.

Strain Measurement: The Foundation of Force Sensors

Strain is the change in length of a material under load. While we cannot directly see force, we can observe how it causes stress in a material, which in turn produces strain. By measuring strain in a calibrated component, we can accurately determine the amount of force applied. This is the principle behind nearly all load cells and force sensors.

What Makes a Force Sensor, a Force Sensor?

There's a common misconception between Force Sensors and Strain Sensors. In the simplest of terms, a force sensor is For example, load cells are a type of force sensor, but require a method of measuring strain in order to function. Without it, a 'load cell' is really just a piece of precisely machined metal. But when fitted with a strain sensor, your nicely machined metal can accurately measure loads up to and exceeding 1000 tonnes. In theory, almost anything could be loosely classified as a force sensor, assuming it was instrumented correctly and had a method of accurately measuring strain.

The most common methods of measuring strain include: Strain Gauge Sensors, Piezoelectric Sensors, and Fibre Optic Sensors, each with their own advantages, limitations, and specific use cases.

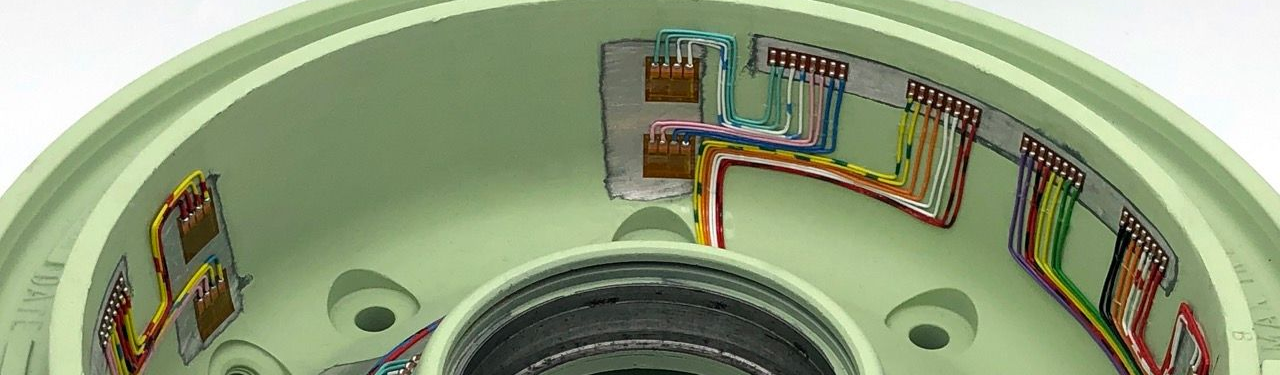

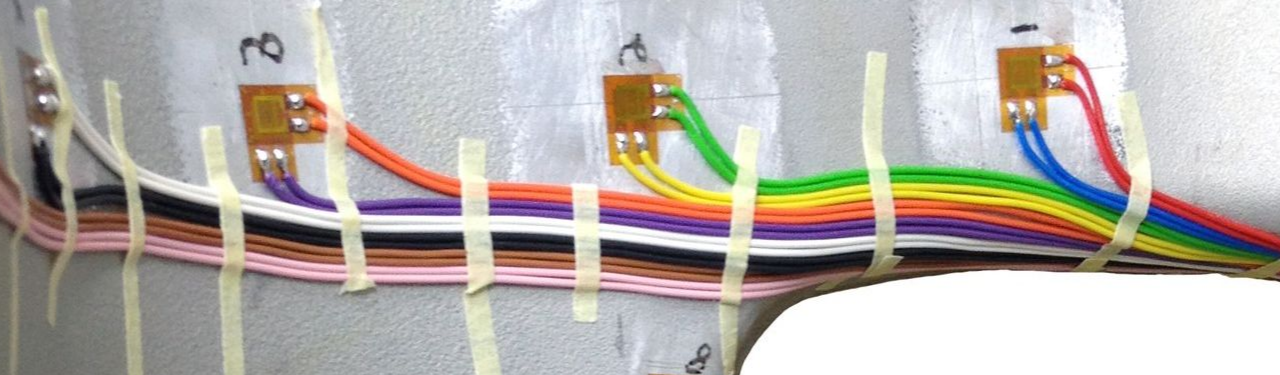

Strain Gauge Sensors

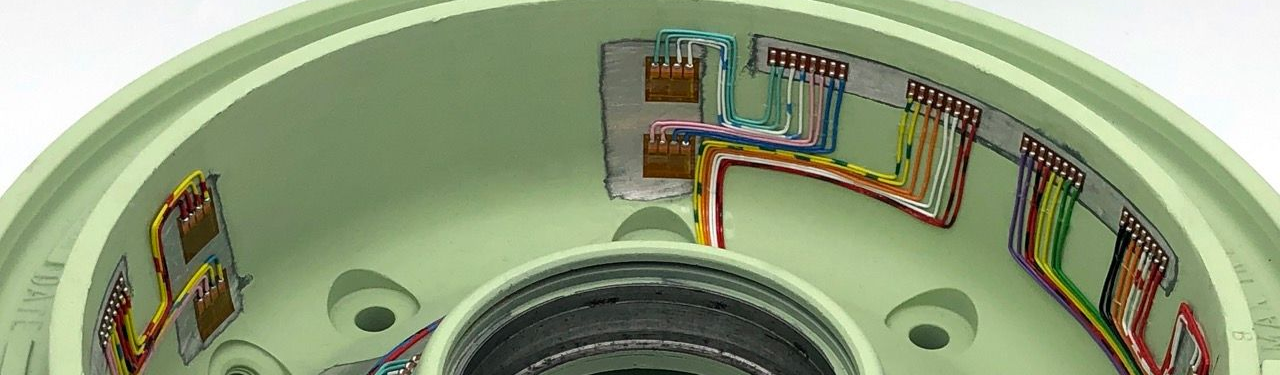

Strain gauges are the most commonly used strain sensors. They are typically made of a fine metallic grid bonded to a structural element. When that element deforms under load, the strain gauge stretches or compresses, causing its electrical resistance to change. This resistance change is then converted into an electrical signal. Finally, once all components have been calibrated, the electrical signal can be translated into the required unit of measurement.

What it measures: Purely mechanical strain along the surface to which it is bonded, through local deformation of the material.

Strengths: Mature technology, highly accurate, widely available, suitable for static and dynamic forces

Limitations: Sensitive to harsh environments when not treated properly, requires expert bonding and calibration for reliable results.

Use Cases: Strain gauges are very common, and typically make their way into most industries, applications, and scenarios

Piezoelectric Sensors

Piezoelectric sensors work on the piezoelectric effect: when certain crystals are stressed, they generate a proportional electrical charge. Unlike strain gauges, which detect resistance change, piezoelectric materials directly convert stress into an electric signal.

What it measures: Stress/strain through generated charge

Strengths: Excellent for dynamic or transient forces (impacts, vibrations etc.)

Limitations: Cannot measure static or long-term forces reliably (charge leakage)

Piezoelectric load cells are commonly used in applications like vibration analysis, impact testing, and dynamic monitoring where fast response is critical.

Fibre Optic Sensors

Fibre optic strain measurement typically uses Fibre Bragg Gratings (FBGs). When the fibre is strained, space between the gratings is either increased (tension) or decreased (compression). This change causes a very precise shift in the wavelength, directly proportional to strain. An optical interrogator is then used to measured the reflected wavelength shift. Once calibrated, the shift can be translated into units of measurement.

What It Measures: Strain via wavelength shift

Strengths: Operates in high-voltage, radioactive, or chemically aggressive environments, lightweight, capable of multiplexing many sensors in a single fibre with extreme precision.

Limitations: Far more expensive, requires specialised interrogation equipment, sensitive to temperature and mechanically harsh environments.

Fibre optic load cells are particularly useful in applications such as MRI machines, power plants, and structures where conventional electronics may fail.

Why The Methods Matter

Understanding the different methods of measuring strain inside a force sensor will give you a better understanding of your application, and may help you to make more informed decisions when looking for a load cell or other style of force sensor.

Get The Best Solution for Your Application

While there are broad guidelines to follow when it comes to choosing the right force sensor, it's not black and white. Each application is unique, and rarely straightforward. If you're looking for the ideal load measurement solution for your application then feel free to get in touch, our experts are always happy to help.