Duration:

Permanent

Hours:

Full-time

37.5 hour working week

Monday-Thursday: 8:30-17:00

Friday: 8:30-14:30

Holidays:

25 days per annum

Plus bank holidays

Location:

On-Site

Closing Date:

8th July 2025

About Us

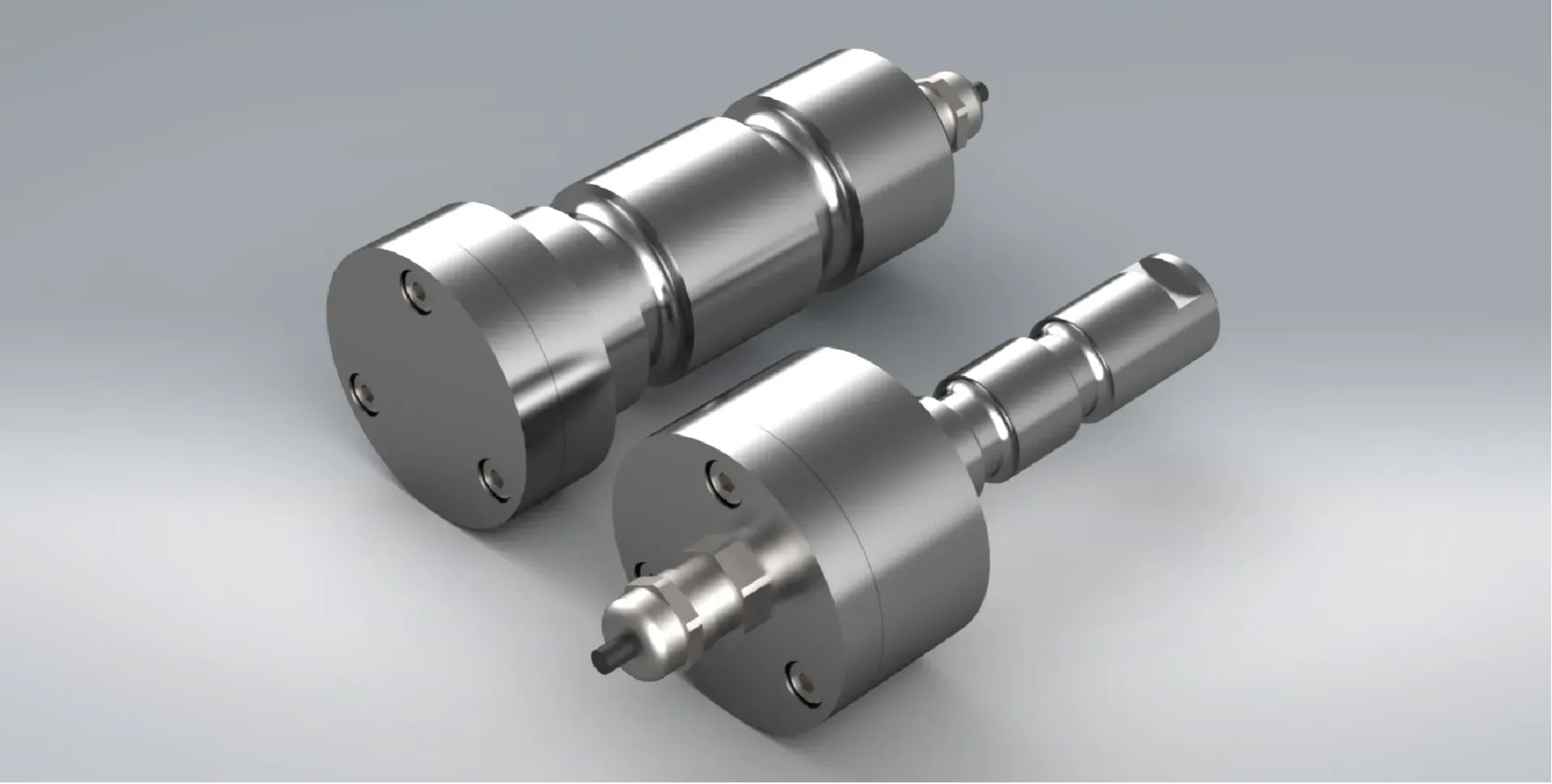

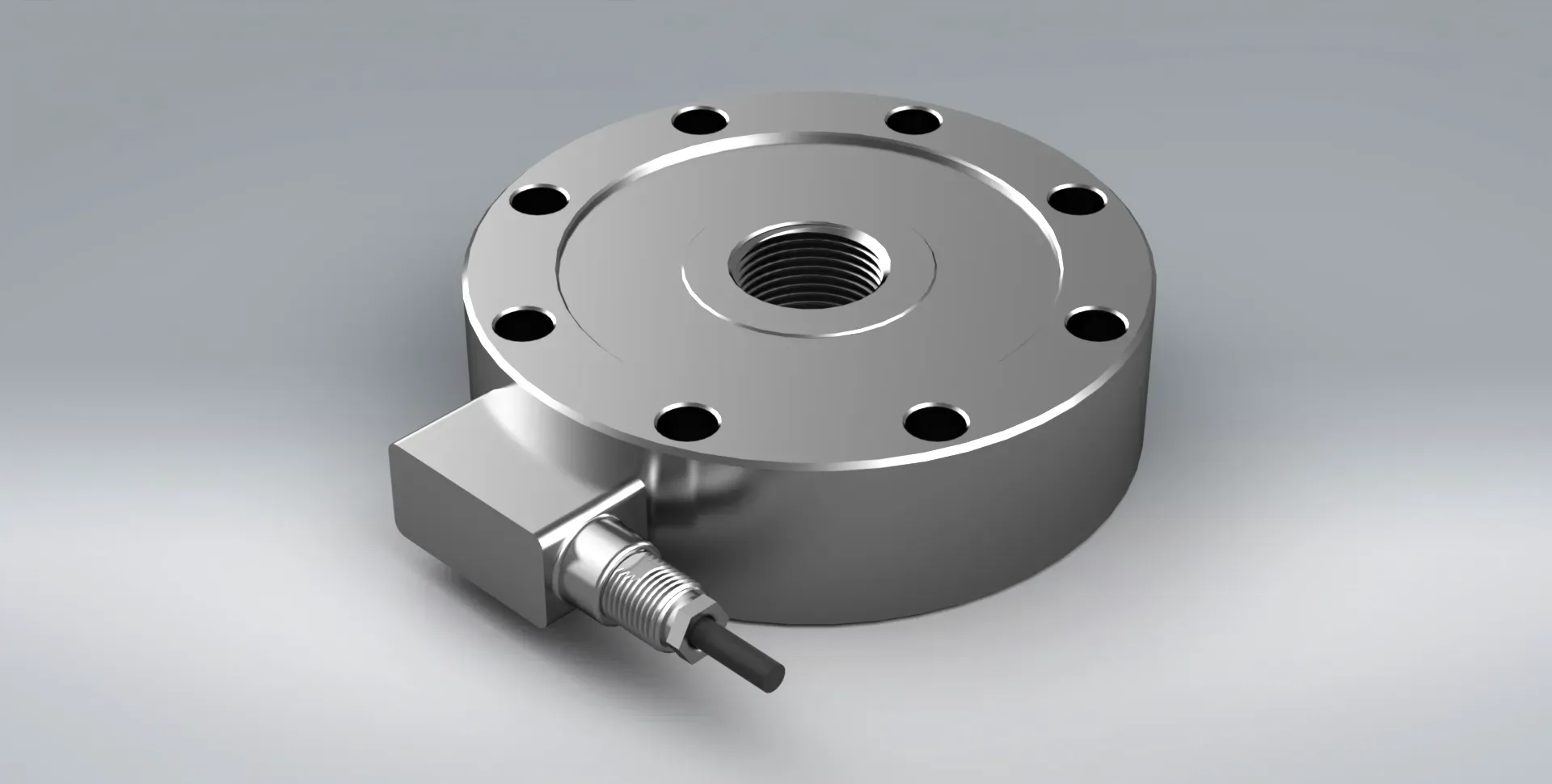

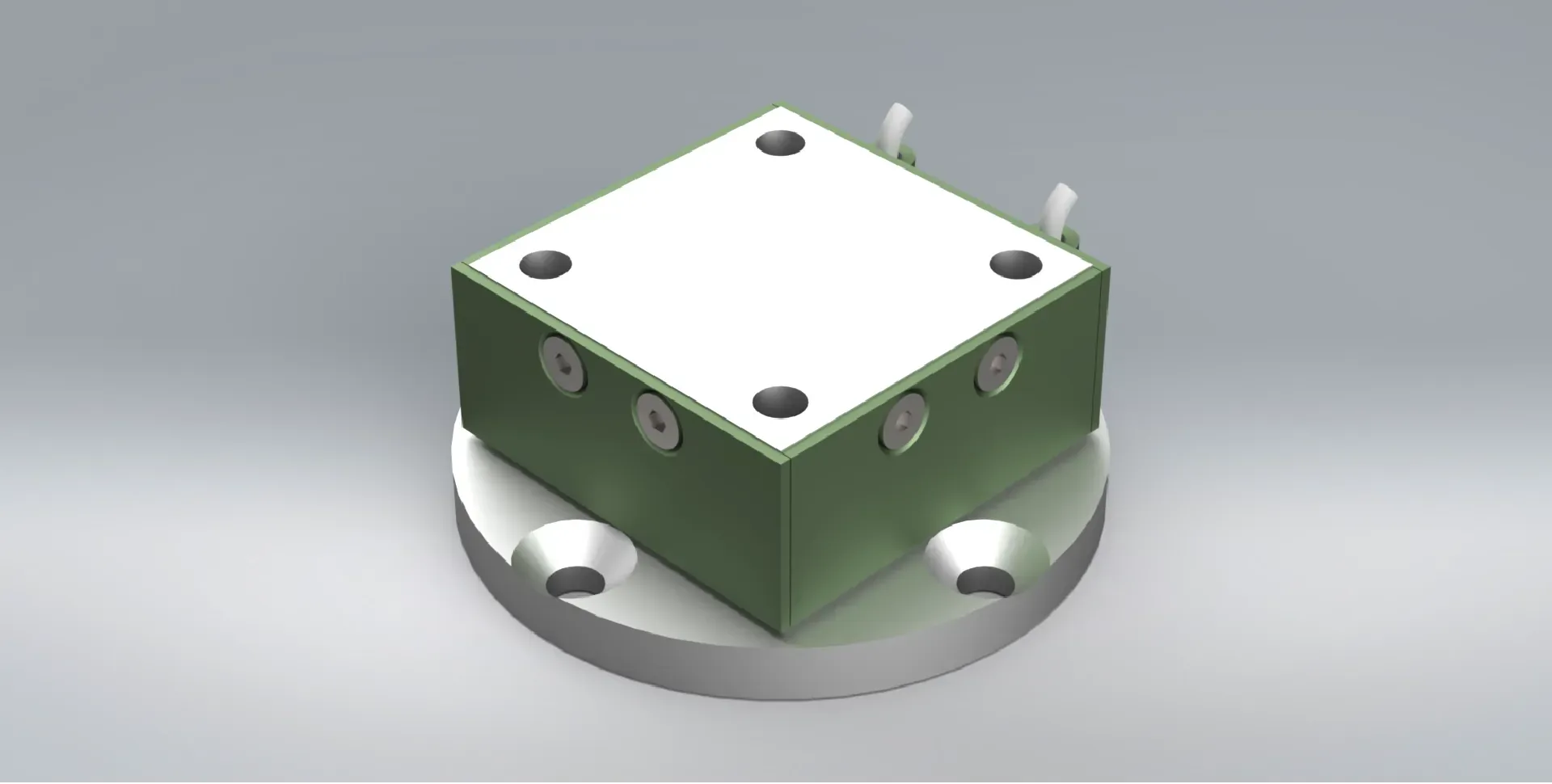

Established in 1983, PCM is a deeply passionate, third generation family business that works with the latest technology to provide load cell manufacture, strain gauge installation and force calibration services that are best in class, globally.

Over the past 40 years, we have continually reinvested in our facilities and developed a wealth of experience, meaning today we are well-equipped to solve the biggest, most unique and most demanding measurement challenges in any engineering sector.

Our reputation for uncompromised quality and precision, combined with our commitment to traceability and continuous improvement (as evidenced by our IS09001 and UKAS 17025:2017 accreditations), sees our skilled team repeatedly trusted by industry leaders to keep their critical operations running smoothly.

Following our recent rebranding, PCM is now expanding as part of our long-term goal to become undisputed, worldwide leaders in the load measurement field.

About The Role

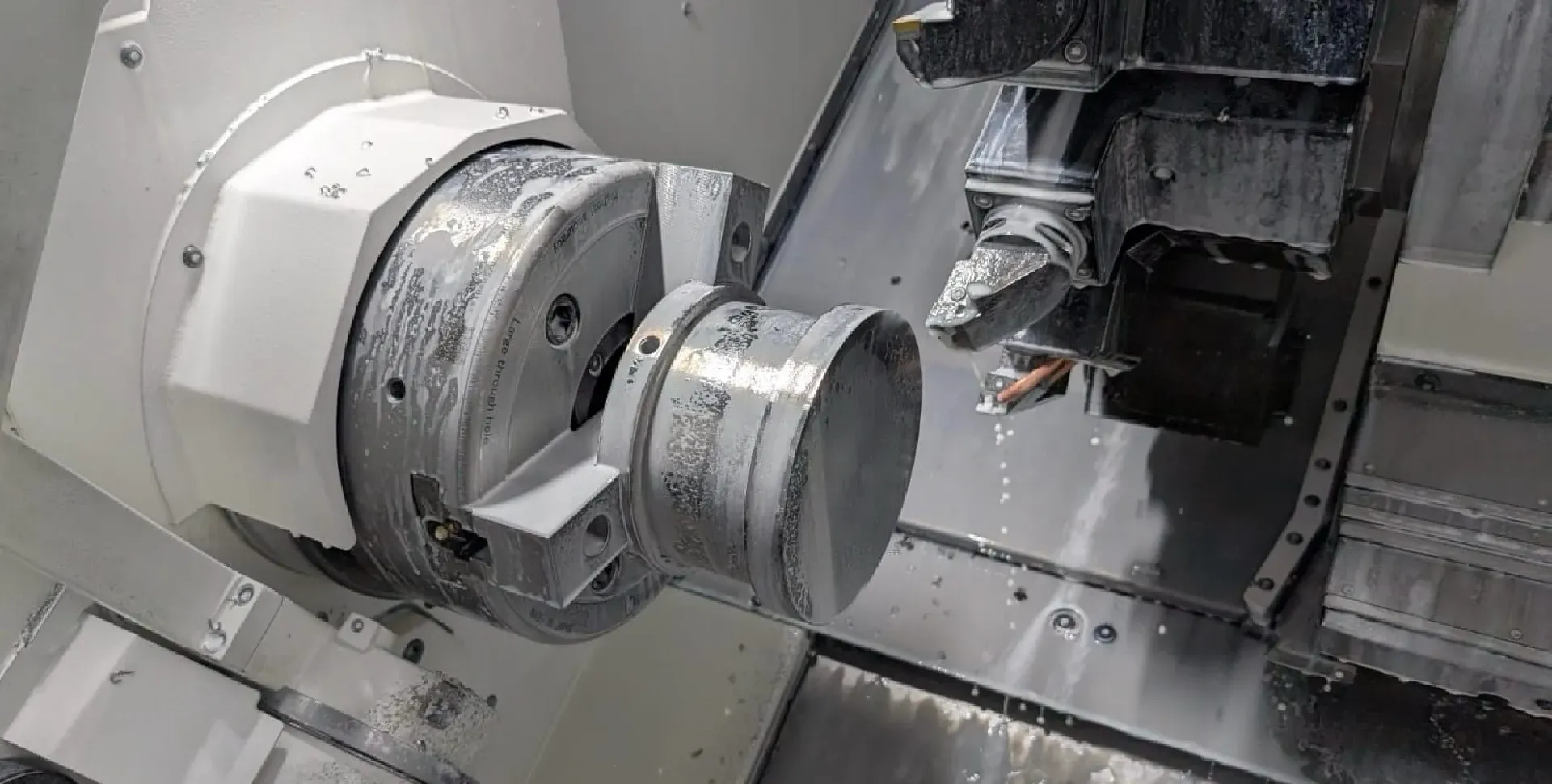

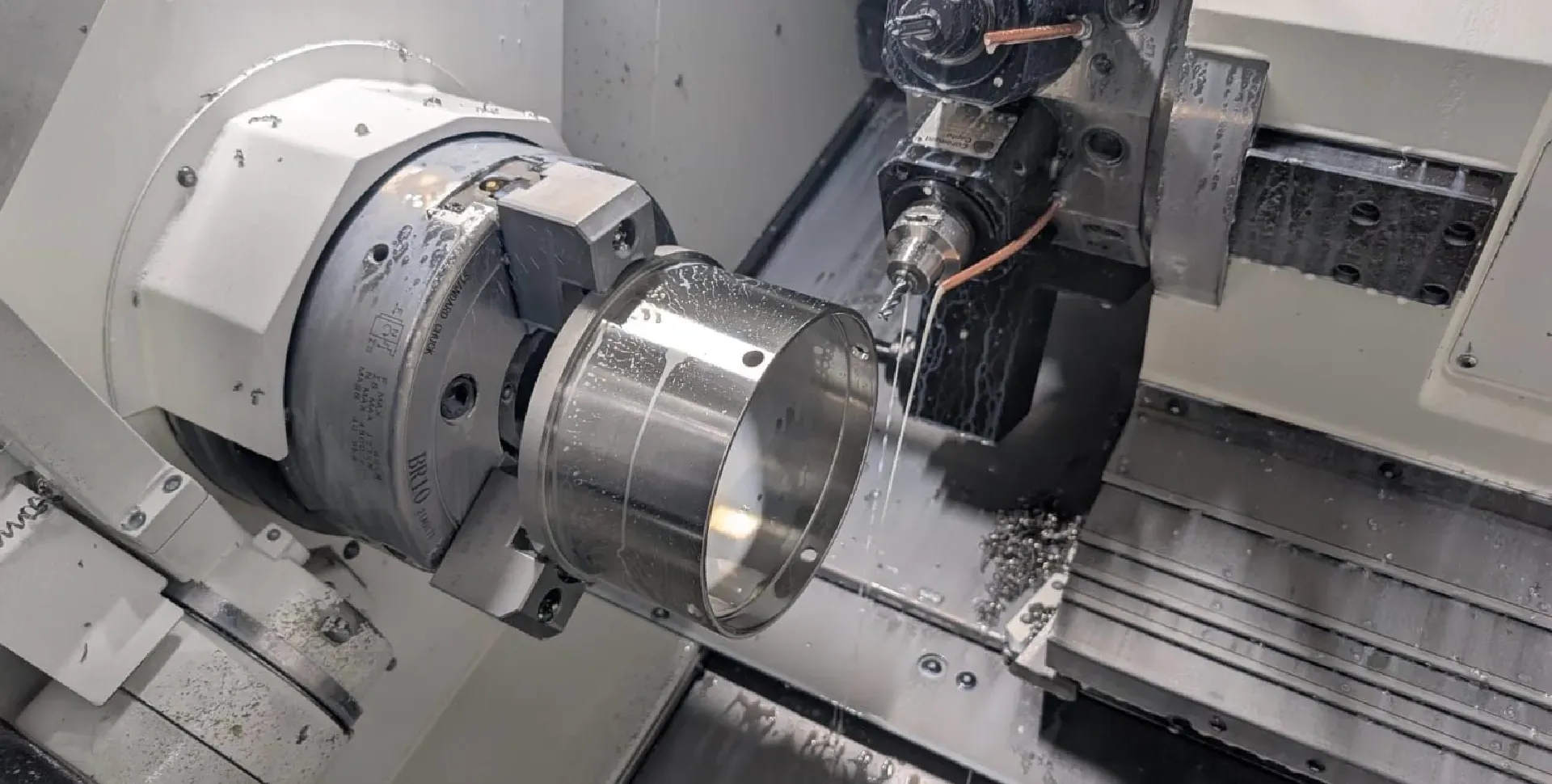

Bringing all machining processes in-house is a journey we embarked upon in September 2023, so that we could gain ultimate control over our manufacturing processes and thus realise improvements in product quality, as well as lead times.

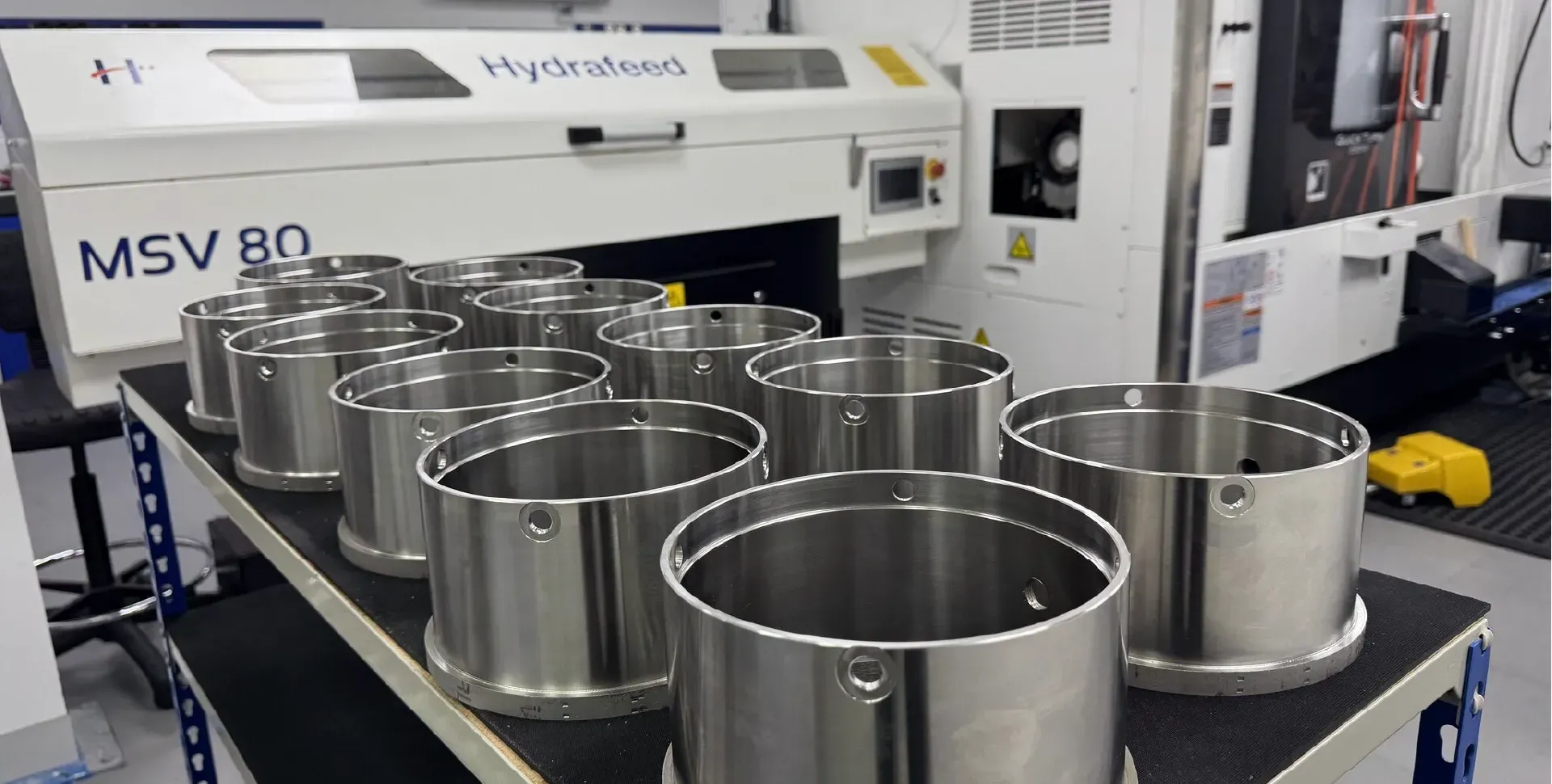

Initially, we’ve been taking things slowly, whilst we learn and develop processes. With strong foundations now in place, we’re in pursuit of an experienced CNC machinist who can scale-up and champion our machining operations, making this new service flourish using the below machines:

Mazak QT-250MY: Mazatrol Smooth G controller, single spindle machine, C axis, Y axis, tailstock, parts catcher, MSV80 bar feeder, Rotary Pro conveyor, 380mm maximum machining diameter, 80mm maximum bar diameter.

Mazak CV5-500: Mazatrol Smooth X controller, 18,000 rpm spindle upgrade, high pressure 70 bar through spindle coolant, Renishaw tool setter & probe, 500mm maximum workpiece diameter, 320mm maximum workpiece height, LANG work holding.

Primarily, you’ll be working on small batch intricate and complex 17-4pH stainless steel parts that are of highly bespoke design. However, you should expect to work on elementary geometries and cut other materials (such as 304 Stainless Steel, EN24T Steel, 2014 Aluminium, and Titanium) also.

Key Responsibilities

- Supporting our technical team with design for manufacture.

- Offline mill-turn and 5 axis milling programming using SolidCAM within the SolidWorks environment.

- Documenting machine set-up procedures within work instructions.

- Selecting appropriate cutting tools, whilst ensuring their proper installation and routine calibration.

- Setting, operating, and maintaining our machines for one-off, small batch and large quantity production runs.

- Proving out and refining G-Code, with any machining issues being identified and resolved accordingly.

- Monitoring machining processes to ensure parts consistently meet our quality standards and specifications.

- Visual and dimensional inspection of parts using hand-held metrology equipment.

- Material handling using our Combilift pedestrian stacker.

- Billet cutting on our Carif 260 BSA bandsaw.

- Laser marking serial/part numbers and PCM branding onto machined items using our Gravotech LW2 machine.

- Ultrasonic cleaning of finished components.

- Ensuring computer-based records are maintained as required.

- Maintaining a safe working environment by adhering to strict safety protocols and maintenance guidelines.

Key Skills

- Able to work autonomously with great accuracy and attention to detail.

- Efficiently manage your own workload through impeccable organisation.

- Practically minded with good hands-on experience.

- Excel at problem solving and have a strong willingness to learn.

- Able to work to deadlines and maintain concentration under pressure.

- Strong team player who is respectful, honest and loyal.

Required Qualifications & Experience

- GCSE English & Maths at Grade C or above.

- 3+ years CAM programming experience and knowledge.

- 3+ years setting and operating Mazak machines in a similar role.

Desirable Qualifications & Experience

- Fully competant at using SolidCAM.

- Setting and operating Mazak QT lathes with live tooling.

- Setting and operating Mazak 5 axis milling machines.

- 17-4PH Stainless Steel machining.